When it comes to mechanical repairs or DIY projects, choosing the right tools is of paramount importance. And when it comes to selecting a ratchet wrench, it's no different. Ratchet wrenches are common hand tools, but the market offers various styles and brands to choose from. To ensure your work goes smoothly and your tool feels comfortable in your hand, careful consideration of a few key factors is necessary. This article will delve into how to choose the ratchet wrench that suits your needs and provide three important guidelines to assist you in making a wise choice.

Table of Contents (Click to read this paragraph)

- How to Choose a Ratchet Wrench? 3 Key Points to Guide You▼

- Ratchet Wrench Set by 【OSK Hand Tools】 - The Preferred Hand Tool Brand of International Automotive Modification Workshops▼

How to Choose a Ratchet Wrench? 3 Key Points to Guide You

When it comes to ratchet wrenches, a vital tool in mechanical work and repairs, the market offers a plethora of types and brands, leaving one wondering how to make the right choice. Fret not! This article will provide you with three crucial points to help you select the ratchet wrench that best suits your needs, making your work a breeze.

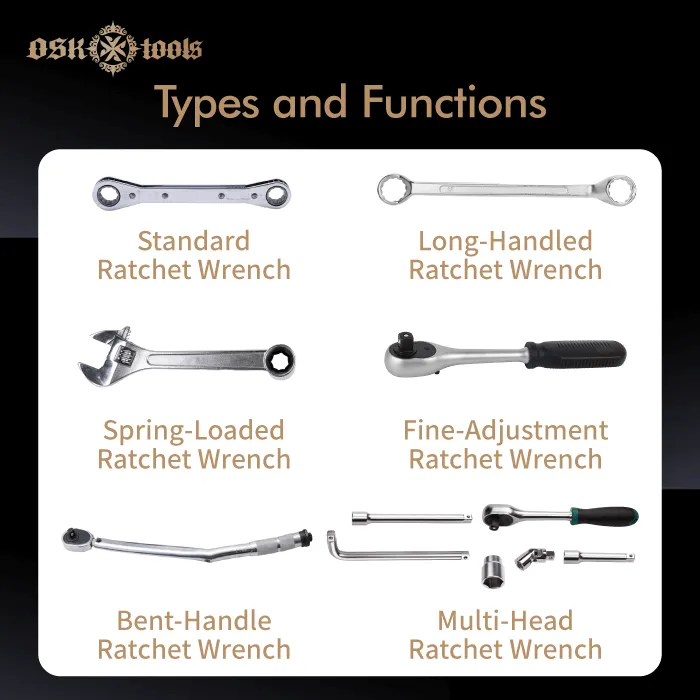

1.Types and Functions of Ratchet Wrenches

The primary purpose of a ratchet wrench is to rotate bolts and nuts. It is commonly used in mechanical maintenance and automobile servicing. Depending on the number of teeth and specific purposes, you can choose a ratchet wrench that is more efficient. Below, we introduce common types and functions of ratchet wrenches.

Standard Ratchet Wrench

The standard ratchet wrench is the most basic type, typically offering bidirectional rotation for clockwise and counterclockwise tightening and loosening of general screws and bolts.

Long-Handled Ratchet Wrench

Long-handled ratchet wrenches have extended handles, providing greater leverage for tasks that require more force, such as wheel bolts or other large screw applications.

Spring-Loaded Ratchet Wrench

Spring-loaded ratchet wrenches feature an internal spring mechanism for quick ratcheting without the need for manual turning, making them ideal for continuous tasks, such as assembly line applications.

Fine-Adjustment Ratchet Wrench

Fine-adjustment ratchet wrenches include a fine-tuning knob for precise angle adjustments, particularly suitable for high-precision work like electronics or precision machinery assembly.

Bent-Handle Ratchet Wrench

Bent-handle ratchet wrenches have curved handles, allowing for use in narrow or hard-to-reach spaces, providing enhanced maneuverability.

Multi-Head Ratchet Wrench

Multi-head ratchet wrenches come with interchangeable heads to accommodate different shapes and sizes of screw heads, enhancing versatility.

Positioning Ratchet Wrench

Positioning ratchet wrenches feature mechanisms that can lock at specific angles, making them easier to use in tight or challenging positions.

Further reading:OSK Tools use Partner-Bill Brinkworth introduce

2.Assessing Techniques for Choosing the Right Ratchet Wrench Set

Selecting the right ratchet wrench set that suits your needs is crucial. Here are some evaluation techniques to make a wise choice based on project requirements:

- Size: Ratchet wrenches come in different sizes, ranging from small ones suitable for tiny screws to larger ones for bigger bolts. Choose an appropriate size to ensure the tool fits your work.

- Quality: The quality of ratchet wrenches affects their durability and performance. High-quality tools typically use stronger materials capable of handling more stress, but they often come at a higher price.

- Mechanism: Ratchet wrenches have varying numbers of teeth, affecting the precision and speed of rotation. Higher tooth counts usually provide finer control, while lower counts offer higher rotational speed.

- Price: Ratchet wrenches come at different price points, ranging from budget-friendly options to high-end precision models. Choose a tool that fits your budget.

- Material: Ratchet wrenches are typically made of steel, but different steel alloys can offer varying performance characteristics. For example, alloy steel is often more robust and less prone to rust.

Considering these factors will help you choose the right ratchet wrench set that suits your needs, ensuring smooth and efficient work.

Further reading:OSK Tools use Partner-Akira Nakai introduce

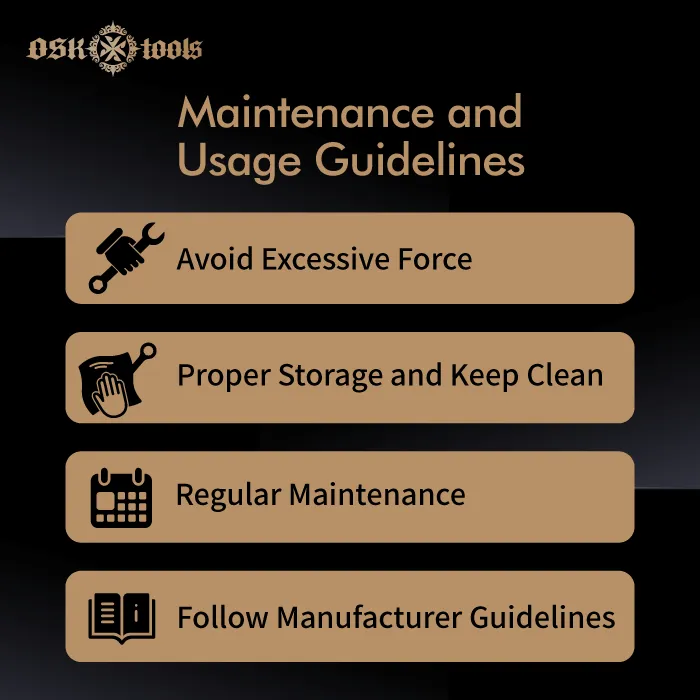

3.Maintenance and Usage Guidelines for Ratchet Wrench Sets

Proper maintenance and usage of your ratchet wrench set are crucial for ensuring its longevity and performance. Here are some essential considerations:

- Regular Inspection: Periodically inspect your ratchet wrench set to ensure there is no wear or damage. Pay particular attention to the gears, ratcheting mechanism, and sockets to ensure they are functioning correctly.

- Avoid Excessive Force: Avoid applying excessive force. While ratchet wrenches are robust, improper use may damage their internal mechanisms.

- Avoid Using as a Lever: Ratchet wrenches should not be used as levers to increase force. This can damage the wrench's gear system.

- Use Proper Sockets: Use the correct size and type of sockets to avoid damaging screw heads or the wrench itself.

- Avoid Using the Handle as a Hammer: Do not use the handle of the ratchet wrench as a hammer, as this can lead to damage.

- Keep Clean: After use, keep your wrench set clean and free from dust and dirt to ensure the internal mechanisms remain uncontaminated.

- Proper Storage: When storing your wrench set, keep it in a dry place away from extreme temperature fluctuations. Use a kit or storage box to prevent damage or loss.

- Regular Maintenance: If your ratchet wrench is used frequently, perform regular maintenance, such as applying lubrication, to ensure smooth operation.

- Follow Manufacturer Guidelines: Adhere to maintenance and usage guidelines provided by the manufacturer to ensure the safety and performance of the wrench set.

Strictly following these guidelines will ensure that your ratchet wrench set remains efficient in use and enjoys a longer lifespan.

Ratchet Wrench Set by 【OSK Hand Tools】 - The Preferred Hand Tool Brand of International Automotive Modification Workshops

After reading this article, I believe everyone has gained a deeper understanding of how to select the right ratchet wrench. If you're a car enthusiast and a proud owner of an automobile, you probably have some basic knowledge of automotive maintenance. Therefore, having a ratchet wrench set for DIY repairs is an excellent choice. By following the assessment techniques outlined in this article, you can select the ratchet wrench set that suits you best. Simple maintenance and taking care of your beloved vehicle become easy and fulfilling tasks. Are you still debating which ratchet wrench set to choose? We recommend selecting various tool sets developed by the renowned international automotive modification brand, 【OSK Hand Tools】. These tool sets allow you to match your specific needs, ensuring you pick the most suitable ratchet wrench. So why wait? Head over to explore the wrenches' performance and bring these practical hand tools home today.

Released on 2023-08-30|Last updated on 2023-12-20 | 3267

OSK Tools-Wrench Brand

Phone: +1 949 372 2831(Click to call)

Facebook:OSK Tools(Click to visit)

FB Messenger:OSK Tools(Click to DM)

Service Time: 09:00-18:00 on weekdays