In the realm of automotive maintenance, efficient and precise tools are the key to success. Ratcheting wrenches are one of the shining stars in this field, renowned for their versatility and practicality. This article delves into three professional applications of these tools, unveiling their indispensable roles in automotive maintenance.

Table of Contents (Click to read this paragraph)

- Applications of Ratcheting Wrenches in Automotive Maintenance: Exploring 3 Professional Uses▼

- OSK Hand Tools Recommends Ratcheting Wrench Set: Non-Slip, Anti-Bite Design for Effortless Automotive Repairs▼

Applications of Ratcheting Wrenches in Automotive Maintenance: Exploring 3 Professional Uses

These three key applications encompass precise fastening and loosening, a compact design suitable for confined spaces, and adjustable control. These areas of application have widespread significance in automotive repair, contributing to the assurance of vehicle safety, performance, and reliability.

As you continue reading, you'll discover how these multifunctional tools serve as valuable companions in the field of automotive repair, providing precision and efficiency to ensure vehicles remain in optimal condition.

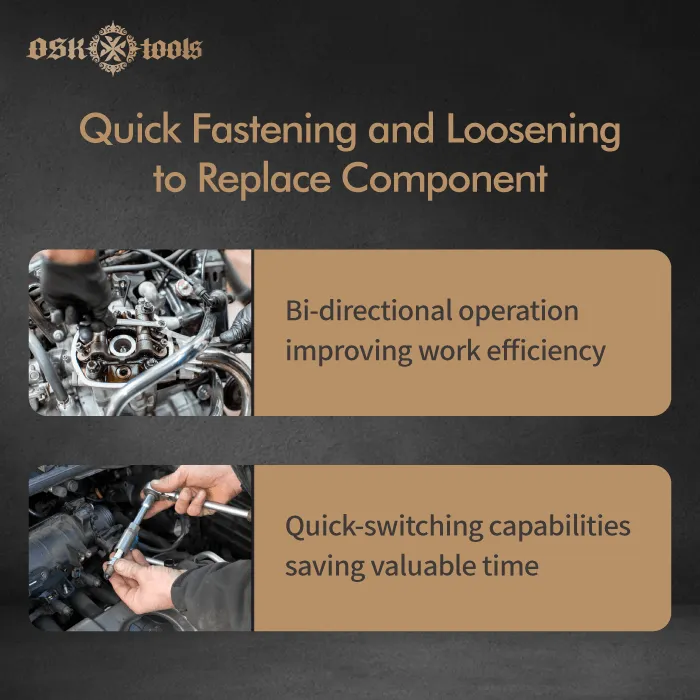

1.Quick fastening and loosening to replace component

In the field of automotive repairs, time efficiency and precision are paramount, especially when it comes to tasks involving rapid screw fastening and loosening. Ratcheting wrenches are a critical tool, providing technicians with a fast and reliable solution for handling various quick screw fastening and loosening operations in vehicle maintenance.

Precise Fastening

Ratcheting wrenches allow technicians to quickly and precisely tighten various screws, such as connecting screws in engine components, or securing bolts in chassis parts. This swift operation makes the maintenance process more efficient while ensuring that all screws meet the manufacturer's specified torque requirements. This not only contributes to safety but also enhances automotive performance and reliability.

Swift Loosening

In vehicle maintenance, there are instances where screws need to be rapidly loosened, such as for part replacements or inspections. The ratcheting mechanism of these wrenches enables technicians to effortlessly release screws, saving valuable time. This swift operation helps boost maintenance efficiency and reduces the vehicle's downtime in the workshop.

Further reading:What is the benefit of a ratcheting wrench?3 benefits why you need ratcheting wrench in your toolbox

Precision

Ratcheting wrenches feature adjustable torque control, allowing technicians to ensure that screws reach precise torque specifications. This is essential for preventing screws from being overtightened or too loose, preventing damage to vehicle components while ensuring safety.

2.Operations in confined spaces

In the field of automotive repairs, there is often a need to work in confined spaces, including narrow or hard-to-reach areas such as the engine bay, chassis, wheel wells, and other regions. In such scenarios, ratcheting wrenches prove their indispensable value by providing the versatility and operational convenience that professional technicians require to tackle various challenges.

Compact Design

Ratcheting wrenches are designed to be extremely compact, allowing them to operate effortlessly in confined spaces. Without the need for extensive swinging motions, technicians can easily use these tools, whether it's in the cramped engine bay or tight areas near the tires. This design makes them an essential tool for such environments.

Quick-Change Mechanism

Ratcheting wrenches come equipped with a quick-change mechanism, enabling technicians to swiftly handle multiple bolts or nuts in tight spaces. This feature enhances operational efficiency, as there is no need for constant handle rotations; technicians can complete tasks rapidly.

Operational Convenience

The operational convenience of ratcheting wrenches is their unique feature, allowing technicians to adapt to various situations without being constrained by limited space. Whether adjustments, disassembly, or assembly is required, these tools offer both convenience and precision in their operation.

Further reading:3 key point of what are the functions of ratchet wrench set in manufacturing and assembly?

3.Vehicle brake system chassis maintenance

In the field of automotive repairs, the maintenance of brake systems and chassis is of paramount importance as they directly impact the vehicle's safety and stability. In these domains, ratcheting wrenches offer the versatility and operational convenience required by professional technicians. Let's provide a detailed explanation of their applications.

Brake System Maintenance

The brake system is at the core of vehicle safety, comprising components like brake discs, brake calipers, brake pads, among others. Ratcheting wrenches are employed for the rapid and precise disassembly and fastening of these parts during brake system maintenance. This ensures the proper operation of the brake system, preventing brake disc wear and ensuring secure fastening of brake calipers.

Chassis Repairs

Chassis repairs encompass work on suspension systems, steering systems, and various chassis components. These tasks often involve disassembling and fastening various sizes and types of screws to replace components or make adjustments. Ratcheting wrenches are multifunctional, capable of addressing various screws while providing reliable torque control to ensure these screws meet specified torque requirements.

OSK Hand Tools Recommends Ratcheting Wrench Set: Non-Slip, Anti-Bite Design for Effortless Automotive Repairs

Through this article, we aim to provide a better understanding of the applications of ratcheting wrenches in automotive repairs. If you're a car enthusiast who enjoys maintaining and repairing your vehicle, we recommend having a ratcheting wrench set on hand, preferably one with a non-slip, anti-bite black chrome-plated design. This type of hand tool allows you to efficiently carry out repair tasks within narrow spaces, making your maintenance work more effective! We recommend the OSK Hand Tools brand of ratcheting wrenches, which feature a durable black chrome plating and have undergone a 96-hour salt spray test to ensure a smoother repair process.

Released on 2023-11-10|Last updated on 2023-12-20 | 962

OSK Tools-Wrench Brand

Phone: +1 949 372 2831(Click to call)

Facebook:OSK Tools(Click to visit)

FB Messenger:OSK Tools(Click to DM)

Service Time: 09:00-18:00 on weekdays