.webp)

Ratcheting wrenches are highly versatile tools used in various applications, from automotive repairs to home improvement tasks. They offer a significant advantage over traditional wrenches by allowing continuous rotation without repositioning the tool. When selecting a ratcheting wrench, one of the most important considerations is how much torque it can handle. This determines the tool's ability to perform under different levels of stress and pressure.

Table of Contents (Click to read this paragraph)

- How much torque can a ratcheting wrench handle? 3 points to tell you▼

- Recommended Ratchet Wrench Set [OSK Hand Tools] 72-Tooth Ratchet Wrench, Making Repairs Easier▼

How much torque can a ratcheting wrench handle? 3 points to tell you

The torque capacity of a ratcheting wrench is influenced by several factors, including its material, design, the number of teeth in the ratcheting mechanism, and the specific usage conditions. By considering these key elements, users can select the right tool for their needs and ensure optimal performance and durability in various applications. Below, this article will explore these three key points that influence a ratcheting wrench’s torque capacity and performance.

1.Material and Design Affect Torque Capacity

The material and design of a ratcheting wrench are key factors in determining the maximum torque it can handle. High-strength alloy steels, such as chrome vanadium or chrome molybdenum, are commonly used to manufacture high-quality ratcheting wrenches due to their excellent tensile strength and wear resistance, which ensure stability under high-stress conditions. These materials provide greater durability and prevent the wrench from deforming or breaking during use.

Regarding design, the structure, handle length, and thickness of the ratcheting wrench are crucial in its torque capacity. A well-designed wrench distributes applied force evenly, reducing the risk of localized stress overload. A longer handle offers better leverage, allowing users to apply more torque with less effort. Additionally, the design of the wrench's gear and pawl mechanism must be carefully considered to ensure that it can withstand high loads without slipping or excessive wear.

2.Number of Teeth in the Ratcheting Mechanism Relates to Precision

.webp)

The internal ratcheting mechanism consists of gears and pawls, which control the movement of the wrench. One key aspect of this mechanism is the number of teeth in the ratchet. A wrench with a higher number of teeth, such as 72 or 90 teeth, allows for more precise control because it requires less movement to engage the next tooth. This is particularly useful when working in tight spaces, where small adjustments are needed.

However, more teeth do not necessarily equate to higher torque capacity. There is often a trade-off between precision and strength. Wrenches with more teeth typically have smaller teeth, which may not be as strong as those in wrenches with fewer, larger teeth. Therefore, while a high-tooth-count wrench provides more precision, it may not handle as much torque as one with fewer teeth but a stronger mechanism. This balance between precision and strength is important when selecting the right wrench for specific tasks.

Further reading: How many teeth on a ratchet is good? 3 keypoint to explain

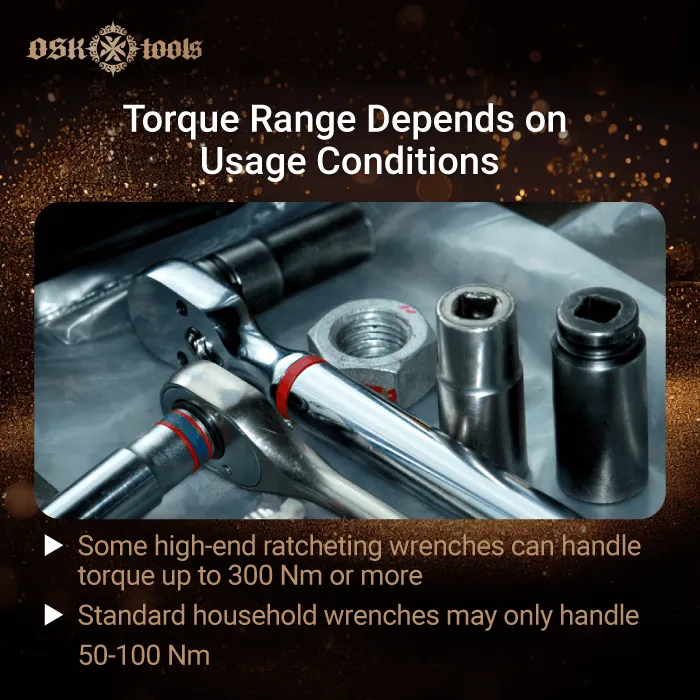

3.Torque Range Depends on Usage Conditions

The torque range of a ratcheting wrench varies based on its intended use and the specific conditions in which it is exposed. Manufacturers often provide a torque range that indicates the maximum force the tool can handle for different applications. For example, heavy-duty or professional-grade ratcheting wrenches are designed to manage high torque loads, often exceeding 300 Nm, which is common in automotive and industrial settings. In contrast, standard household wrenches may have a lower torque capacity, typically between 50 and 100 Nm, sufficient for lighter tasks. The working conditions, such as the type of bolts or fasteners and the environment, can also influence the wrench’s performance and longevity.

Further reading: Can you use a ratchet instead of a torque wrench? 3 point ley you know

Recommended Ratchet Wrench Set [OSK Hand Tools] 72-Tooth Ratchet Wrench, Making Repairs Easier

Understanding how much torque a ratcheting wrench can handle is essential for selecting the right tool for the job. The material and design of the wrench greatly influence its torque capacity, with high-strength alloy steel providing greater durability and strength. While the number of teeth in the ratcheting mechanism affects precision, it does not necessarily mean the wrench can handle higher torque. Finally, the torque range varies depending on the wrench’s intended use, with professional-grade tools offering higher torque ratings than those for household tasks. By considering these factors, users can ensure they choose a ratcheting wrench that meets their specific needs.

The 【OSK Hand Tools】 72-Tooth Ratchet Wrench is an excellent choice for making repairs easier and more efficient. With its high tooth count, it offers precision and smooth operation even in tight spaces. The black chrome coating provides exceptional slip resistance and durability, while its ability to pass the 96-hour salt spray test ensures long-lasting protection against corrosion. This wrench is a must-have for both professionals and DIY enthusiasts looking for reliability and performance. If you need a wrench, head over to the wrench section and make your purchase now!

Released on 2024-09-13|Last updated on 2024-09-25 | 2976

OSK Tools-Wrench Brand

Phone: +1 949 372 2831(Click to call)

Facebook:OSK Tools(Click to visit)

FB Messenger:OSK Tools(Click to DM)

Service Time: 09:00-18:00 on weekdays