Choosing the right tool is essential for mechanical work and repairs. SAE and metric ratcheting wrenches follow different measurement systems and vary in application and availability. Understanding these differences helps improve efficiency and prevents damage caused by incorrect sizing.

Table of Contents (Click to read this paragraph)

- SAE vs. metric ratcheting wrench differences 4 points to explain▼

- Ratcheting wrench recommendation: 【OSK Hand Tools】 100% pure black chrome coating for slip-resistance and durability▼

SAE vs. metric ratcheting wrench differences 4 points to explain

When selecting a ratcheting wrench, you may notice both SAE and metric options. The key differences lie in their size standards and areas of use, which directly impact their practicality. Whether for automotive repair, machinery assembly, or general maintenance, knowing these distinctions allows you to make informed decisions.

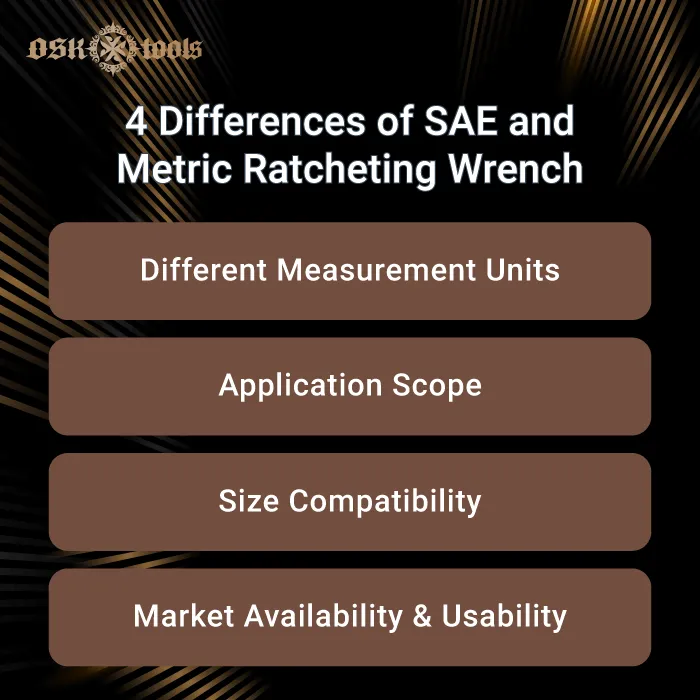

1.Different Measurement Units

SAE (Society of Automotive Engineers) ratcheting wrenches use imperial units (inches), with sizes typically expressed as fractions, such as 1/4", 3/8", and 1/2". In contrast, metric ratcheting wrenches use millimeters (mm), with sizes like 6mm, 10mm, and 13mm. This difference in measurement standards affects precision and applicability. In mechanical maintenance and manufacturing, using the correct unit-specific tool is crucial to prevent damage to bolts and nuts, ensuring proper equipment functionality and safety.

2.Application Scope

The usage of SAE and metric ratcheting wrenches depends on manufacturing standards and regional requirements. Choosing the correct tool ensures precision and safety in maintenance tasks. Below are the primary applications for each type:

SAE Ratcheting Wrenches

- Primarily used for vehicles, machinery, and industrial equipment manufactured in the U.S. and Canada.

- Common in U.S. standard construction, plumbing, and aerospace industries.

- Frequently used in American car brands like Ford, Chevrolet, and Dodge.

Metric Ratcheting Wrenches

- Widely applied in European, Asian, and internationally standardized machinery and equipment.

- Suitable for most modern imported vehicles, including Toyota, BMW, and Mercedes-Benz.

- More prevalent in electronics, manufacturing, and precision engineering due to compliance with ISO (International Organization for Standardization) standards.

Further reading:Can a ratcheting wrench replace a breaker bar 3 point will help you understand

Due to globalization, many vehicles and machines incorporate both SAE and metric specifications. As a result, professional technicians often need both types of wrenches to ensure flexibility and precision in maintenance work.

3.Size Compatibility

In some cases, certain SAE and metric ratcheting wrench sizes are close enough to be used interchangeably for short-term applications. Examples include:

- 3/8" racheting wrench (approximately 9.525mm) can be substituted with 10mm

- 1/2" racheting wrench (approximately 12.7mm) is close to 13mm

- 1/4" racheting wrench (approximately 6.35mm) is close to 7mm

Further reading: Do ratcheting wrench come in metric sizes? 3 key professional points to explain

However, this compatibility is not perfect. Prolonged use of mismatched wrenches can lead to bolt and nut damage, such as stripping, deformation, or improper tightening, which may compromise equipment functionality and safety.

Additionally, high-precision or high-torque applications—such as aerospace, precision machinery, and automotive engine repairs—typically require exact-size tools to ensure optimal assembly and durability. Therefore, selecting the appropriate SAE or metric wrench based on equipment specifications is crucial for maintaining an efficient and safe working environment.

4.Market Availability & Usability

The availability of SAE and metric ratcheting wrenches varies by region and industry standards. SAE wrenches are mainly used in North America (U.S. and Canada) for domestically made vehicles, machinery, and construction. However, their demand is lower in Europe and Asia, where only some American-made equipment still requires them.

In contrast, metric wrenches are globally widespread, especially in Europe, Asia, and standardized mechanical industries. They are essential for imported vehicles, electronics, and manufacturing, with ISO adoption making them the industry standard.

As modern machinery often combines SAE and metric components, professionals typically need both types of wrenches to ensure efficiency and accuracy.

Ratcheting wrench recommendation: 【OSK Hand Tools】 100% pure black chrome coating for slip-resistance and durability

Understanding the differences between SAE and metric ratcheting wrenches helps you make the best choice for mechanical and repair tasks. Factors such as measurement units, application scope, size compatibility, and market availability all influence tool performance. To ensure efficiency and precision, selecting high-quality tools is essential. OSK hand tools offer exceptional durability and precision-engineered SAE and metric ratcheting wrenches, making them ideal for various professional and DIY applications. Whether you're a technician or an enthusiast, OSK is a trusted choice to enhance your workflow and efficiency.

Released on 2025-02-06|Last updated on 2025-02-21 | 188

OSK Tools-Wrench Brand

Phone: +1 949 372 2831(Click to call)

Facebook:OSK Tools(Click to visit)

FB Messenger:OSK Tools(Click to DM)

Service Time: 09:00-18:00 on weekdays