Having a sturdy and reliable wrench is crucial for any toolbox. However, sometimes even the best tools can encounter issues. Knowing how to troubleshoot when your wrench faces a dilemma can be immensely helpful. This article will explore four possible solutions to assist you in fixing your wrench, ensuring smooth progress in your work.

Table of Contents (Click to read this paragraph)

- How to fix a ratcheting wrench not turning problem?4 point let you know▼

- Ratcheting Wrench Recommendation: [OSK Hand Tools] Durable Black Chrome Coating, Non-Slip, the Preferred Choice for Maintenance Tools▼

How to fix a ratcheting wrench not turning problem?4 point let you know

Wrenches are essential tools in various tasks, but when they fail to function properly, they can cause inconvenience. Fortunately, many wrench problems can be resolved through simple repairs. In this article, we will discuss four possible solutions to help you fix your wrench and get your work back on track.

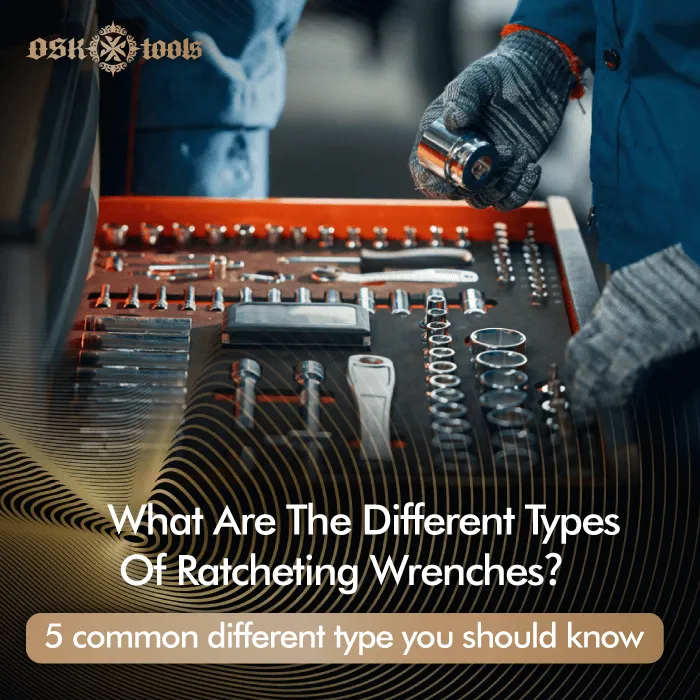

1.Check the gears

Check the gears can help you inspect and repair the gears to resolve the issue of "ratcheting wrench not turning." Remember to prioritize safety and use appropriate tools and techniques before conducting any repair work.

Then verify that the gears mesh properly. If any looseness or abnormal alignment is observed, further adjustment or replacement of corresponding parts may be necessary.

First,ensure Safety.Before conducting any inspection or repair, make sure the wrench is placed on a stable surface and its switch is in the off position to prevent any accidents.

After completing the above steps, close the wrench and perform a test to ensure the gears can rotate freely and the wrench operates properly. If the problem persists, consider further inspection or seek professional assistance.

2.Lubrication

Lubrication is vital for maintaining smooth operation of the wrench. Proper lubrication can reduce wear and friction, prolong tool life, and enhance work efficiency. Below is a professional and comprehensive explanation:

- Identify Lubrication Points: Before lubricating, first identify the critical lubrication points on the wrench. These points are typically where gears and screw threads make contact. Lubricating these areas will help reduce friction and promote smooth movement.

- Select the Proper Lubricant: Choosing the right lubricant is essential. Select a lubricant appropriate for your wrench model and as recommended by the manufacturer. Generally, mechanical tools often use lighter lubricating oils or multi-purpose lubricants.

- Application of Lubricant: Apply the lubricant to the contact surfaces of gears, screw threads, and other moving components. Be careful not to overapply the lubricant to avoid excessive buildup or contamination.

- Distribute the Lubricant: Ensure the lubricant is evenly distributed across the lubrication points. You can use a brush, lubricant sprayer, or dedicated lubricator for application.

Further reading:What is the differences in tooth count for ratcheting wrench?3Q&A explain detail

3.Inspect the spring

Inspecting the spring is a crucial step in resolving the issue of "ratcheting wrench not turning." Here is a professional and comprehensive explanation:

1.Safety Check

Before conducting the inspection, ensure the wrench is placed on a stable surface and in the closed position to prevent any accidents.

2.Locate the Spring

The spring is typically located within the main mechanism of the wrench. Use appropriate tools to gently open the wrench to access the spring.

3.Check the Spring Condition

Inspect the spring for any bending, breakage, or deformation. The spring should have good elasticity and should not show any signs of significant damage. If there are any issues with the spring, replacement may be necessary.

4.Verify Spring Position

nsure the spring is in the correct position and meshes well with other components. Incorrect installation or positioning of the spring may affect the operation of the wrench.

5.Reinstallation

If the spring needs replacement or reinstallation, follow the manufacturer's recommendations. Ensure the spring is properly installed and meshes well with other components.

Further reading:Is a ratchet better than a wrench? 3 topic analysis

4.Clean the interior

Cleaning the interior is an important step in ensuring the proper functioning of the wrench. Thorough internal cleaning helps remove accumulated dirt and debris, thus restoring the wrench's operational capability.

- Open the Wrench

- Remove Dust and Debris

- Check for Damage

- Reassembly

Ratcheting Wrench Recommendation: [OSK Hand Tools] Durable Black Chrome Coating, Non-Slip, the Preferred Choice for Maintenance Tools

Through this article, everyone can gain a clear understanding of how to maintain ratcheting wrenches. The structure of ratchets is relatively more complex compared to regular wrenches, consisting of pawls, gears, and ratchets. Disassembling and maintaining them requires special attention to every detail of each component. Therefore, it is essential to pay extra attention during daily use and maintenance. It is also advisable to choose sturdy and durable ratcheting wrenches from the beginning.

Matte finish wrenches with black chrome plating, for example, prevent slipping and ensure that the wrenches do not fall off or get damaged. Recommended ratcheting wrenches from [OSK Hand Tools] employ black chrome plating, passing the 96-hour salt spray test, ensuring long-lasting usability. If you have wrench needs, head over to the wrench section now to make your purchase!

Released on 2024-03-29|Last updated on 2024-04-09 | 2637

OSK Tools-Wrench Brand

Phone: +1 949 372 2831(Click to call)

Facebook:OSK Tools(Click to visit)

FB Messenger:OSK Tools(Click to DM)

Service Time: 09:00-18:00 on weekdays