In the realm of mechanical tools, ratcheting wrenches and non-ratcheting wrenches stand out as two common yet crucial types. They exhibit significant differences in design and application, influencing their performance in various work environments.

Table of Contents (Click to read this paragraph)

- Exploring Three Distinct Differences Between Ratcheting and Non-Ratcheting Hand Tools▼

- Ratcheting Wrench Recommendations from OSK Tools: A Selection of up to 12 Sizes to Meet Diverse Maintenance Needs▼

Exploring Three Distinct Differences Between Ratcheting and Non-Ratcheting Hand Tools

This article delves into the distinctions between the two, focusing on three major differences to assist readers in better understanding the considerations for choosing the right tool. Let's explore together what sets ratcheting wrenches and non-ratcheting wrenches apart in the fields of engineering and manufacturing.

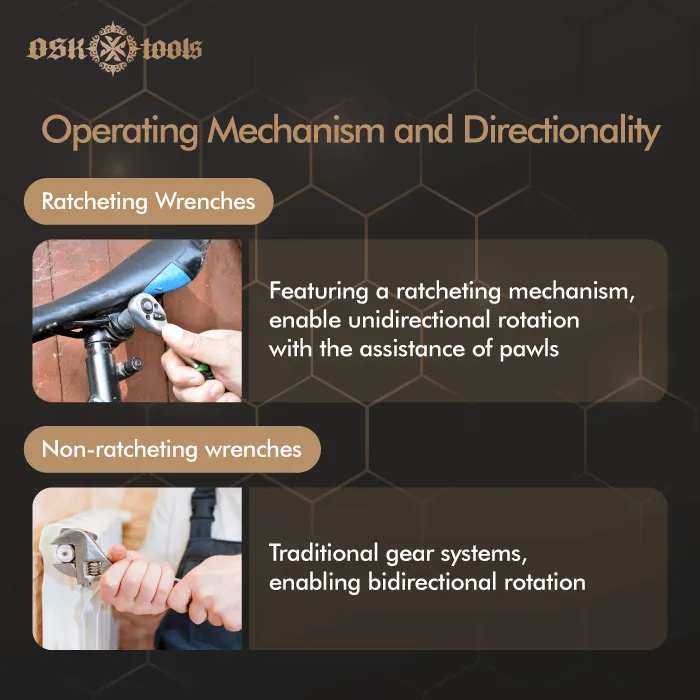

1.Operating Mechanism and Directionality

We will focus on the significant distinctions in the operation and directional aspects of these two manual tools.

Firstly, ratcheting wrenches are renowned for their unique ratcheting mechanism. This mechanism includes one or more pawls, allowing the tool to rotate in one direction while freely rotating in the opposite direction. This design enables ratcheting wrenches to provide unidirectional high torque, particularly suitable for stable and forceful tightening operations.

In contrast, non-ratcheting wrenches may employ alternative mechanisms, such as traditional gear drives or clutch systems. This design allows non-ratcheting wrenches to achieve bidirectional rotation or other specialized operations. However, it also means that in specific unidirectional applications, they may lack the torque stability of ratcheting wrenches.

In summary, the differences in operating mechanisms and directionality between these two tools impact their applicability in different work scenarios, and users should choose the appropriate tool based on specific job requirements.

Further reading:What is the best size ratcheting wrench? 4 common sizes introduction

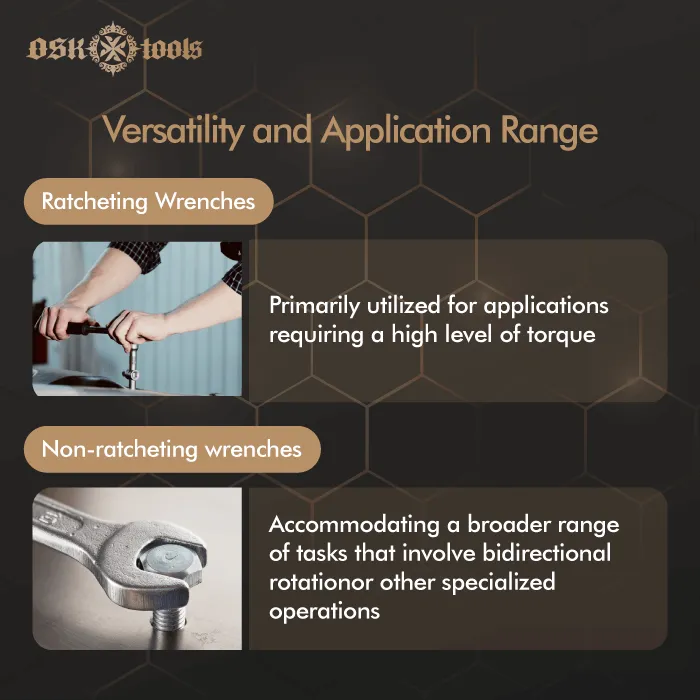

2.Versatility and Application Range

The differences in versatility and application range between these two tools impact their practical applications in their respective fields, and users should consider specific job requirements when making a choice.

- Ratcheting wrenches: Primarily utilized for applications requiring a high level of torque, such as tightening or loosening bolts during mechanical work. The unidirectional torque output makes them particularly suitable for tasks in confined spaces.

- Non-Ratcheting wrenches:Non-ratcheting tools offer greater versatility, accommodating a broader range of tasks that involve bidirectional rotation or other specialized operations. They are well-suited for tasks ranging from light assembly work to the maintenance of electronic equipment.

Further reading:3 Applications of ratcheting wrenches in automotive repairs

3.Complexity and Precision

When comparing the precision and complexity of non-ratcheting wrenches and ratcheting wrenches, attention is drawn to the operational characteristics of these two manual tools.

Firstly, non-ratcheting wrenches typically excel in precision due to their intricate mechanism design, enabling finer and more controlled movements during operations. This precision makes non-ratcheting wrenches particularly suitable for tasks requiring accurate tightening of bolts or delicate assembly work. However, achieving such high precision may involve more complex mechanisms and manufacturing processes.

In contrast, ratcheting wrenches may compromise a bit on precision, prioritizing reliable high-torque output. Their complexity is relatively lower, making them easier to manufacture and maintain. This design makes ratcheting wrenches especially suitable for applications that demand powerful operations without the need for extremely high precision.

In summary, the choice between non-ratcheting and ratcheting wrenches should be based on the specific requirements of the application, striking a balance between precision and complexity.

Ratcheting Wrench Recommendations from OSK Tools: A Selection of up to 12 Sizes to Meet Diverse Maintenance Needs

Through this article, everyone has gained a certain level of understanding about the differences between ratcheting wrenches and non-ratcheting wrenches. Regardless of the type of wrench used, in addition to personal preferences, it is essential to consider the current situation and needs to choose the wrench that truly fits the task, thereby enhancing maintenance efficiency.

If choosing a ratcheting wrench, pay attention to the coating – opt for a matte finish ratcheting wrench with a black chrome coating. Not only does this provide anti-slip properties, but it also ensures smoother operations in confined spaces, making your maintenance work safer and more efficient!

For recommended ratcheting wrenches, consider the OSK Hand Tools brand. Their tools feature a black chrome coating and have passed a 96-hour salt spray test, ensuring long-lasting usability. If you have wrench needs, head to the wrench section now and make your purchase!

Released on 2024-02-05|Last updated on 2024-02-26 | 1531

OSK Tools-Wrench Brand

Phone: +1 949 372 2831(Click to call)

Facebook:OSK Tools(Click to visit)

FB Messenger:OSK Tools(Click to DM)

Service Time: 09:00-18:00 on weekdays