In the realm of hand tools, the choice between matte and glossy finish ratcheting wrenches presents a significant decision point for both professional tradespeople and DIY enthusiasts. The surface finish of a ratcheting wrench can impact its functionality, durability, and overall performance in various working environments. This article delves into the nuances of matte and glossy finishes, highlighting three key points to help you grasp the distinctions between these options.

Table of Contents (Click to read this paragraph)

- Differences Between Matte and Glossy Finish Ratcheting Wrenches: 3 Points to Help You Understand▼

- OSK Hand Tools Matte Ratcheting Wrench Passes 96-Hour Salt Spray Test for Effortless Repairs▼

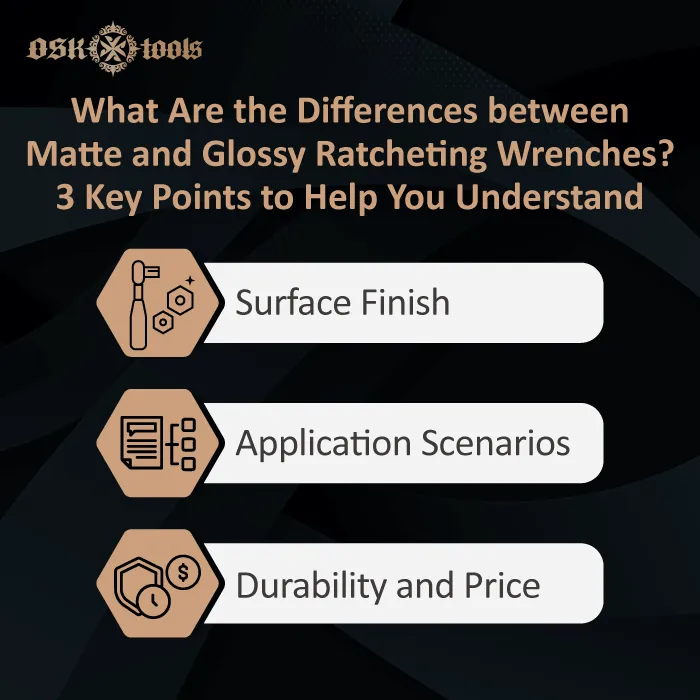

Differences Between Matte and Glossy Finish Ratcheting Wrenches: 3 Points to Help You Understand

This article will explore three key differences between matte and glossy finishes on ratcheting wrenches to provide you with a deeper understanding of the characteristics of these two surface treatments. Whether you're a professional tradesperson or a DIY enthusiast, gaining insights into these distinctions will assist you in making informed decisions when choosing and using wrenches.

1.Ratcheting wrenches surface Finish

Matte Finish

Matte finish is achieved through processes such as sanding or chemical treatments, creating a rough texture with subtle grain on the wrench's surface. This finish excels in providing superior grip during work, helping to prevent hand slippage, especially in damp or oily conditions.

On the other hand, electroplated black chrome is a specialized surface treatment technique, often applied on top of matte finishes, to provide additional corrosion resistance and wear resistance. This treatment not only enhances the tool's durability but also increases its oxidation resistance, making it particularly suitable for use in harsh environments.

Glossy Finish

Glossy finish is usually achieved through methods like polishing or chrome plating, rendering the wrench's surface smooth and highly reflective. This finish imparts a modern and upscale appearance to the wrench, making it suitable for display or situations where a clean and stylish look is essential, such as household repairs or mechanical tool sets.

Glossy finish elevates the wrench's corrosion resistance and ease of cleaning, as stains are less likely to adhere to the smooth surface. They perform well in light to moderate use and non-extreme environmental conditions.

2.Ratcheting wrenches application Scenarios

Matte Ratcheting Wrenches

Matte finish is typically employed in environments where extra grip is required, such as wet, oily, or dusty conditions. Its rough surface texture provides excellent anti-slip properties, aiding in preventing hand slippage in slippery or unstable conditions.

This treatment makes matte ratcheting wrenches highly practical in industrial maintenance, vehicle servicing, and mechanical engineering, where stability and grip are essential.

Further reading:3 Guides of Using Ratchet Wrench Sets for Precision Fastening

Glossy Ratcheting Wrenches

Glossy finish is often used in situations that demand a clean and modern appearance, such as household repairs, electronics assembly, or tool displays. Its smooth and shiny appearance makes it more appealing, easy to clean, and aesthetically pleasing.

Wrenches with this treatment are well-suited for specific applications, especially those where presentation or customer interaction is a priority.

3.Ratcheting wrenches durability and Price

Durability

Matte ratcheting wrenches typically offer higher durability due to their rough surface, which better resists scratches and wear. This makes them an ideal choice for long-term or heavy-duty use, particularly in working environments with a high risk of mechanical abrasion.

Further reading:3 compare of ratchet wrench sets vs. impact wrenches: which is Right for You

Glossy ratcheting wrenches, while having their advantages, tend to be less durable because their smooth surface is susceptible to scratches. They are better suited for lighter use or applications where long-term durability is not a primary concern.

Price

Matte ratcheting wrenches are generally relatively more expensive because their production process involves additional treatment steps and they offer greater durability. However, this also means they typically represent a long-term investment value as they can endure for extended periods.

Glossy ratcheting wrenches are usually more budget-friendly as their production costs are lower. They are an ideal choice for shorter-term or light-duty use, especially when budget constraints are a consideration.

OSK Hand Tools Matte Ratcheting Wrench Passes 96-Hour Salt Spray Test for Effortless Repairs

Through this article, we hope to provide you with a better understanding of the differences between matte and glossy ratcheting wrenches. For those who love working on cars and enjoy the maintenance process, owning a set of ratcheting wrenches with a black chrome plating that resists fingerprints is a great choice. This can prevent fingerprints from smudging your tools, making your repair and manufacturing work more efficient. We recommend the OSK tool brand for ratcheting wrenches, as their tools feature a durable black chrome plating and have undergone a 96-hour salt spray test, extending their lifespan and becoming a valuable partner in enhancing your efficiency.

Released on 2023-10-27|Last updated on 2023-12-20 | 1303

OSK Tools-Wrench Brand

Phone: +1 949 372 2831(Click to call)

Facebook:OSK Tools(Click to visit)

FB Messenger:OSK Tools(Click to DM)

Service Time: 09:00-18:00 on weekdays