Understanding the internal components of a ratcheting wrench is crucial for both users and manufacturers. For users, it ensures proper usage and maintenance, leading to extended tool life and reliable performance. For manufacturers, it aids in designing more efficient and durable wrenches, ultimately benefiting the end-users with higher-quality tools.

Table of Contents (Click to read this paragraph)

- What is inside a ratcheting wrench? 6 part of ratcheting wrench▼

- Ratchet Wrench Set by 【OSK Hand Tools】 - The Preferred Hand Tool Brand of International Automotive Modification Workshops▼

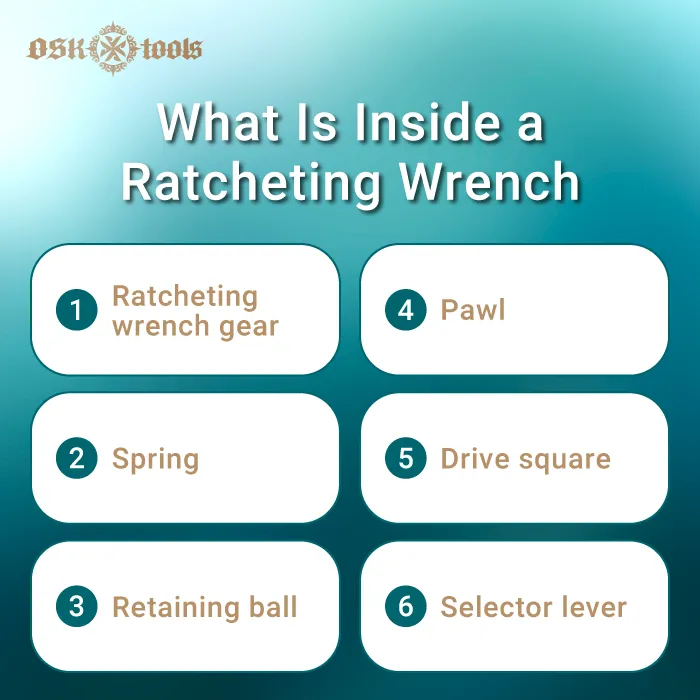

What is inside a ratcheting wrench? 6 part of ratcheting wrench

A ratcheting wrench is renowned for its ability to efficiently tighten or loosen fasteners without the need to lift the wrench off the fastener repeatedly. The intricate engineering within a ratcheting wrench makes this possible, with 6 key components playing crucial roles: the gear, pawl, spring, drive square, retaining ball, and selector lever.

1.Ratcheting wrench gear

At the core of the ratcheting mechanism is the gear, a toothed wheel that interacts with the pawl. The number of teeth on the gear can vary, directly affecting the precision of the wrench. A gear with more teeth allows for finer adjustments and smoother operation since it requires less movement to engage the next tooth. This makes the wrench highly effective in tight spaces where there is limited room for movement.

Further reading: How many teeth on a ratchet is good? 3 keypoint to explain

2.Pawl

The pawl is a lever that engages with the gear teeth, permitting rotation in one direction while preventing it in the opposite direction. This engagement is essential for the ratcheting action, allowing the wrench to apply torque in one direction without slipping back when the handle is moved in the reverse direction. The design and material of the pawl are critical for ensuring durability and reliable performance under varying loads.

3.Spring

The spring provides the necessary tension to keep the pawl engaged with the gear. Without the spring, the pawl would not maintain consistent contact with the gear teeth, resulting in slippage and inefficiency. The spring ensures that the pawl remains in the correct position, allowing the user to apply continuous pressure without losing grip on the fastener. The strength and durability of the spring are vital for the longevity and reliability of the ratcheting mechanism.

4.Drive square

The drive square is the square-shaped end where sockets attach, available in various sizes for different applications. This part of the wrench is designed to fit standard sockets, enabling the wrench to be used with a wide range of fasteners. The drive square's compatibility with different socket sizes adds to the tool's versatility, making it indispensable in both professional and home settings.

Further reading: What is the best size ratcheting wrench? 4 common sizes introduction

5.Retaining ball

To secure the socket to the drive square, a small ball bearing known as the retaining ball is used. This ball bearing fits into a groove on the socket, holding it firmly in place during operation. The retaining ball ensures that the socket does not slip off the drive square, even under significant torque. This feature is particularly important when working with stubborn fasteners that require substantial force to loosen or tighten.

6.Selector lever

The selector lever is the mechanism used to change the direction of the ratcheting action. Located on the head of the wrench, this lever allows the user to switch between tightening and loosening modes quickly. The ability to change direction without removing the wrench from the fastener streamlines the workflow, saving time and effort. The selector lever's design and placement are crucial for user convenience and efficient operation.

Ratchet Wrench Set by 【OSK Hand Tools】 - The Preferred Hand Tool Brand of International Automotive Modification Workshops

In summary, a ratcheting wrench is a sophisticated tool that combines several components to deliver efficient and precise performance. The gear, pawl, spring, drive square, retaining ball, and selector lever work together harmoniously to enable the ratcheting action, making it an essential tool for mechanics and DIY enthusiasts alike. Understanding the functions of these components helps in appreciating the engineering behind this indispensable tool.

We highly recommend the 【OSK Hand Tools】 for ratcheting wrenches. These tools come with a black chrome coating and have successfully passed a 96-hour salt spray test, guaranteeing that the coating remains intact while providing a comfortable and secure grip. If you need a ratcheting wrench, head over to the wrench section and make your purchase now!

Released on 2024-07-19|Last updated on 2024-08-02 | 2040

OSK Tools-Wrench Brand

Phone: +1 949 372 2831(Click to call)

Facebook:OSK Tools(Click to visit)

FB Messenger:OSK Tools(Click to DM)

Service Time: 09:00-18:00 on weekdays