In mechanical and machinery maintenance tasks, using the right tools can greatly enhance efficiency and precision. One widely used tool in this regard is the quick-release ratchet. This tool not only speeds up operations but also simplifies the maintenance process, enabling workers to accomplish tasks more effectively. In the following, we will delve into the definition, features, and applications of the quick-release ratchet.

Table of Contents (Click to read this paragraph)

- What is a quick release ratchet? 3 key point explained▼

- Recommended OSK Hand Tool Brand: 12 Diverse Sizes of Convenient Ratchet Tools, Swiftly Completing Maintenance Tasks▼

What is a quick release ratchet? 3 key point explained

Typically, these ratchets have a movable socket, and users simply press a release button to quickly insert or remove sockets. This significantly saves time and enhances efficiency, especially in scenarios requiring frequent socket changes. Three key points characterize quick-release ratchets: reliable locking, rapid operation, and durable design, making them a preferred tool for many mechanical workers and enthusiasts.

1.Functional description

The functional description of a quick release ratchet highlights its efficient design and user-friendly features. By enabling swift socket changes without compromising performance, this tool proves invaluable in various industries and applications, streamlining tasks and optimizing productivity.

Quick release ratchet components

- Handle: The handle of a quick release ratchet provides a comfortable grip, allowing users to maintain precise control during operation.

- Ratchet head: The ratchet head houses the socket and features a mechanism for directional rotation, enabling efficient tightening or loosening of fasteners.

- Quick release mechanism: This is one of the distinctive features of a quick release ratchet, enabling rapid socket changes without the need for additional tools.

Quick release ratchet advantages

- Time savings: The quick release feature eliminates the need for manual socket changes, saving valuable time during tasks that require frequent socket adjustments.

- Enhanced efficiency: With seamless socket interchangeability, users can maintain workflow momentum without interruptions, leading to increased efficiency.

- Convenience: The convenience of rapid socket changes simplifies operations, particularly in scenarios where multiple socket sizes are needed.

Further reading:How to Choose a Comfortable Grip Wrench? 3 Key Points to Guide You

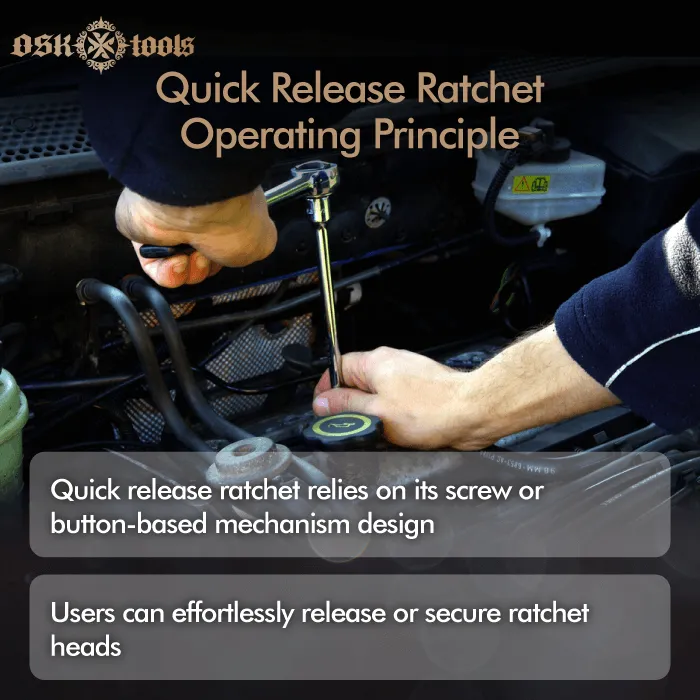

2.Operating principle

The operating principle of a quick release ratchet is based on its unique mechanical design, which incorporates a convenient mechanism to achieve rapid socket changes, thereby enhancing work efficiency.

Socket fixing mechanism

In a quick release ratchet, the socket fixing mechanism is a key component. This mechanism is typically implemented in the form of screws or buttons located inside the ratchet head.

When a socket is inserted into the ratchet head, the fixing mechanism ensures that the socket is securely held in place, providing stability and safety during operation.

Quick Release Mechanism

The quick release mechanism is a key feature of a quick release ratchet. Typically located at the bottom or side of the ratchet head, this mechanism can be activated by pressing a button or rotating a component.

When a socket change is needed, users can operate the quick release mechanism to release the current socket and install a new one, enabling fast and uninterrupted operation.

Further reading:What is the best size ratcheting wrench? 4 common sizes introduction

3.Application scope

The rapid socket changing feature has a wide range of applications, here are some common ones:

- Automotive Maintenance: In the automotive repair industry, the rapid socket changing feature is used for disassembling and assembling wheel nuts, engine components, and other vehicle parts, saving time and increasing repair efficiency.

- Mechanical Manufacturing: In the process of mechanical manufacturing, the rapid socket changing feature is used for assembling and disassembling mechanical parts, such as bolts and nuts, to expedite the manufacturing process and enhance production efficiency.

- Construction Engineering: In the construction field, the rapid socket changing feature is used for assembling and disassembling building structures, installing and adjusting bolts, screws, and other fasteners, thereby accelerating the construction progress and improving work efficiency.

- Home DIY Projects: In home repairs and DIY projects, the rapid socket changing feature is used for furniture assembly, household appliance repairs, and other home maintenance tasks, making operations more convenient and saving time.

Recommended OSK Hand Tool Brand: 12 Diverse Sizes of Convenient Ratchet Tools, Swiftly Completing Maintenance Tasks

Through this article, everyone should have a clear understanding of the Quick Release Ratchet function. In addition to the quick release feature of the ratchet, the selection of ratchet tools also needs to consider the size and space of the site. Choosing ratchet tools suitable for different occasions can improve maintenance efficiency. Furthermore, the coating of ratchet tools also affects the user experience. Choosing a matte panel hand tool with black chrome plating can not only prevent slipping but also make operations in narrow spaces smoother making your maintenance work safer and more efficient!

Recommended ratchet hand tools from OSK hand tool brand use black chrome plating, and pass the 96-hour salt spray test, maintaining a comfortable feel for long periods of use. If you also need ratchet tools, go to the ratchet tool section now and make your purchase!

Released on 2024-03-01|Last updated on 2024-03-08 | 1660

OSK Tools-Wrench Brand

Phone: +1 949 372 2831(Click to call)

Facebook:OSK Tools(Click to visit)

FB Messenger:OSK Tools(Click to DM)

Service Time: 09:00-18:00 on weekdays