In the realm of mechanical repairs or assembly work, the terms "socket wrench" and "ratcheting wrench" are frequently mentioned tools. However, there exists a crucial distinction between the two. This article aims to delve into the similarities and differences between these two wrench types, offering insights to help you better comprehend their respective applications and advantages.

Table of Contents (Click to read this paragraph)

- Is socket wrench same as ratcheting wrench? 3 differences to show you▼

- The Ratcheting Wrench Recommended Choice72-Tooth Design, Ensuring Stable Rotation for Task Completion▼

Is socket wrench same as ratcheting wrench? 3 differences to show you

While the socket wrench and the ratcheting wrench may seem similar at first glance, there are significant differences between them. The following discussion will highlight three distinctions to help you better understand their respective applications and suitable scenarios.

1.Mechanism of operation

The socket wrench and the ratcheting wrench exhibit notable differences in their operational mechanisms, impacting their efficiency and applications in various work scenarios.

Firstly, the socket wrench relies primarily on a complete circular motion, requiring users to rotate the entire wrench to tighten or loosen screws and nuts. In contrast, the ratcheting wrench incorporates a ratcheting mechanism within, allowing it to engage with fasteners in one direction while freely spinning in the opposite direction. This one-way ratcheting action eliminates the need to reposition the wrench after each turn, particularly beneficial in confined spaces or situations with restricted movement.

Further reading:What is the principle of ratcheting wrench? 3 key points to understand

Secondly, the socket wrench necessitates the swapping of sockets for different screw or nut sizes, potentially requiring the user to carry multiple sockets, which can be somewhat cumbersome. On the other hand, the ratcheting wrench often comes as a set with fixed-size heads, providing a more intuitive and convenient selection.

Lastly, while the socket wrench can accommodate various sizes and types of screws and nuts, it may be less effective in tight spaces. In contrast, the ratcheting wrench, although potentially constrained in the flexibility of sockets, excels in confined spaces and scenarios requiring rapid and continuous movements.

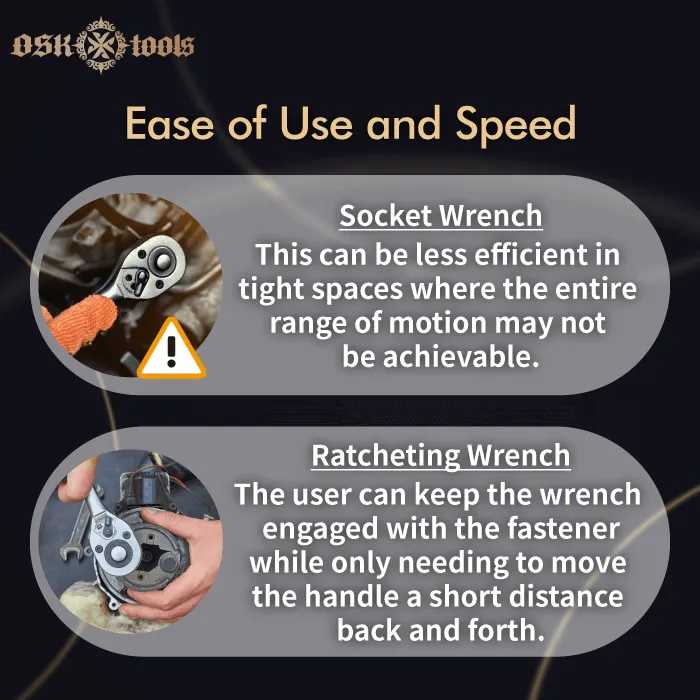

2.Ease of use and speed

The socket wrench and the ratcheting wrench exhibit significant differences in terms of user convenience and speed, directly impacting the efficiency of these tools in practical operations. Here is a comparison of their characteristics in this regard:

Socket Wrench

- Operation Method: Requires a complete circular motion, which may be less flexible in confined spaces or situations with restricted movement.

- Speed: After each turn, there may be a need to lift and reposition the wrench, potentially reducing the operational speed.

Ratcheting Wrench

- Operation Method: Features a one-way ratcheting action, making it more convenient for continuous operation in one direction without the need for repeated lifting and repositioning.

- Speed: In confined spaces or scenarios requiring rapid and continuous movements, the operational speed may be higher due to the absence of additional actions.

Further reading:What are the different types of ratcheting wrenches,5 common different type you should know.

3.Versatility and flexibility

The socket wrench and the ratcheting wrench differ in their versatility and flexibility, impacting their ability to handle various application scenarios and working conditions.

Socket Wrench

- Versatility: Due to the ability to interchange different-sized sockets, the socket wrench is versatile in handling screws and nuts of various sizes and types.

- Flexibility: While flexible, it requires carrying multiple sockets to accommodate different screw and nut sizes, which can be cumbersome in specific situations.

Ratcheting Wrench

- Versatility: The ratcheting wrench often comes as a set with fixed-size heads, limiting its versatility to the sizes included in the set.

- Flexibility: While flexible in some aspects, the fixed head sizes may impose restrictions when dealing with a variety of screw and nut sizes.

Wrench recommendation from OSK hand tools: precision engineering, Perfect fit for All fasteners without slipping

Through this article, everyone can gain a deeper understanding of the differences between a socket wrench and a ratcheting wrench. Whether it's a ratcheting wrench or a socket wrench, each has its advantages and specific applications. When choosing hand tools, you can select the type of wrench that feels most comfortable based on different situations and personal preferences. Regardless of the type of wrench, it is recommended to choose a matte wrench with a black chrome coating, which prevents fingerprints and enhances the efficiency of your maintenance and manufacturing work. The ratcheting wrench recommended here is from the OSK hand tool brand, featuring a durable black chrome coating that has passed a 96-hour salt spray test, ensuring resistance to paint chipping and maintaining a comfortable and stable grip. If you have wrench needs, head to the wrench section now and make your purchase!

Released on 2023-12-14|Last updated on 2023-12-22 | 3027

OSK Tools-Wrench Brand

Phone: +1 949 372 2831(Click to call)

Facebook:OSK Tools(Click to visit)

FB Messenger:OSK Tools(Click to DM)

Service Time: 09:00-18:00 on weekdays