Table of Contents (Click to read this paragraph)

- How to grease a ratchet wrench? 4 steps to grease your ratcheting wrench▼

- Ratcheting Wrench Recommendation: [OSK Hand Tools] Durable Black Chrome Coating, Non-Slip, the Preferred Choice for Maintenance Tools▼

How to grease a ratchet wrench? 4 steps to grease your ratcheting wrench

Regularly maintaining your tools is essential to ensure their longevity and optimal performance, and a ratcheting wrench is no exception. Proper lubrication keeps the mechanism smooth and efficient. This guide will walk you through a comprehensive four-step process to grease your ratcheting wrench, ensuring it remains in top working condition.

1.Prepare the Necessary Tools and Lubricant

Before you begin, gather all the necessary tools and materials. You will need:

- The ratcheting wrench

- A cleaning cloth

- A small brush (such as an old toothbrush)

- Lubricant (machine oil or specialized grease)

Having everything ready and within reach will streamline the process, making it easier and more efficient.

2.Clean the Ratcheting Wrench

Thoroughly cleaning your ratcheting wrench is a crucial step. Over time, dirt, debris, and old lubricant can accumulate, affecting the wrench's performance. Use a cleaning cloth to wipe down the exterior and a small brush to get into the tighter spaces of the ratchet mechanism. Pay special attention to the gears and bearings, as these areas are critical for smooth operation. Removing all contaminants will ensure that the new lubricant can work effectively, providing the necessary protection and reducing friction.

Further reading: How to maintain ratcheting wrench? 3 point you must know

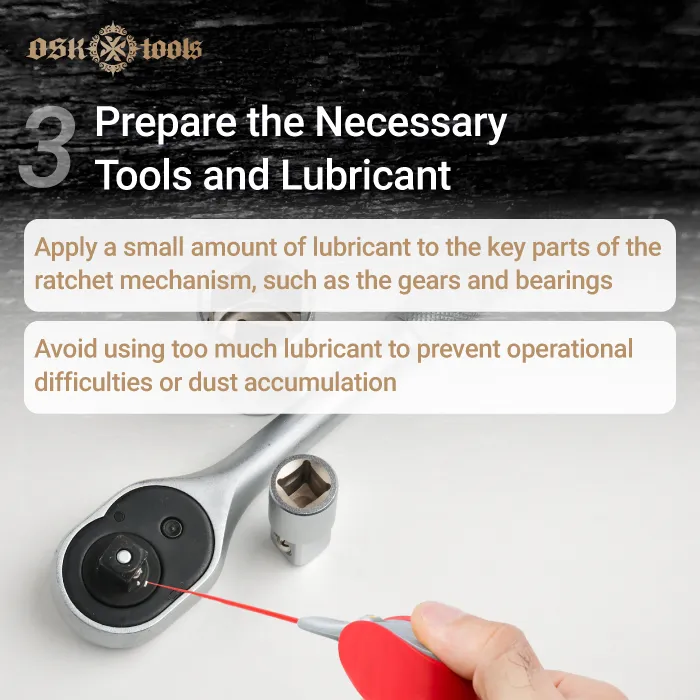

3.Lubricate the Ratchet Mechanism

Once the wrench is clean and dry, it’s time to apply the lubricant. Use a small amount, as too much can attract dust and dirt, potentially leading to operational difficulties. Focus on the key components of the ratchet mechanism. Start by applying a small amount of lubricant directly to the teeth of the gears, as these are the heart of the ratcheting mechanism. Next, lubricate the bearings to ensure they rotate smoothly. Distribute the lubricant evenly across these parts. If you are using a spray lubricant, apply it in short bursts to avoid over-saturation.

4.Test and Adjust

After lubricating, test the ratcheting wrench by operating it several times. This helps distribute the lubricant evenly across the mechanism. If you notice any stiffness or uneven operation, you may need to adjust the amount of lubricant or reapply it to certain areas. Proper adjustment ensures smooth and efficient performance.

Further reading: How to fix a ratcheting wrench? 4 possible solutions help you fix the problem

Ratcheting Wrench Recommendation: [OSK Hand Tools] Durable Black Chrome Coating, Non-Slip, the Preferred Choice for Maintenance Tools

Regular lubrication is vital for maintaining functionality and extending the lifespan of your ratcheting wrench. By following these four detailed steps, you ensure that your tool remains in excellent condition, and ready for any task. Proper maintenance not only enhances performance but also prevents wear and tear, saving you from costly repairs or replacements in the long run. Make this routine part of your tool care regimen, and your ratcheting wrench will serve you well for years to come.

Choosing a sturdy and durable matte black chrome-plated ratcheting wrench is recommended, which is non-slip and not easy to fall. These ratcheting wrenches are durable and built to last, making them an ideal long-term choice. The recommended [OSK Hand Tools] ratchet wrench is black chrome plated and passed the 96-hour salt spray test to ensure long-term durability. If you need a ratcheting wrench, head over to the wrench section now to make your purchase!

Released on 2024-07-12|Last updated on 2024-07-18 | 3046

OSK Tools-Wrench Brand

Phone: +1 949 372 2831(Click to call)

Facebook:OSK Tools(Click to visit)

FB Messenger:OSK Tools(Click to DM)

Service Time: 09:00-18:00 on weekdays