Maintaining a ratcheting wrench is crucial for ensuring its longevity and optimal performance. Whether for everyday household use or professional industrial applications, proper maintenance can extend the tool's life and ensure accuracy and safety with each use.

Table of Contents (Click to read this paragraph)

- How to maintain ratcheting wrench? 3 point tell you the right way to maintain your ratcheting wrench▼

- Recommended ratcheting wrench: 【OSK Hand Tools】 96-hour black chrome plating, practical and non-slip▼

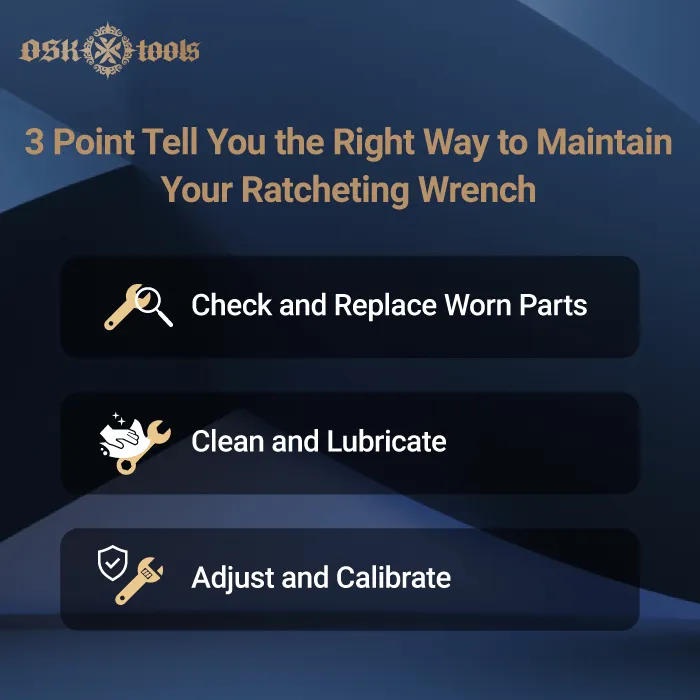

How to maintain ratcheting wrench? 3 point tell you the right way to maintain your ratcheting wrench

This article will introduce three essential maintenance tips for your ratcheting wrench to keep it in top condition. These simple yet important steps will ensure your tool remains in excellent working order, avoiding unnecessary wear and damage.

1.Check and Replace Worn Parts

Regularly inspecting the components of your ratcheting wrench is a crucial maintenance step. First, examine the gears and ratchet teeth inside the ratchet mechanism for signs of wear or damage. If you find any damaged, deformed, or excessively worn gear teeth, replace these parts immediately. This ensures the smooth operation of the ratcheting wrench and prevents issues such as slipping or failure to lock during use.

Next, check the torque spring and other internal springs to ensure they maintain their elasticity and proper tension. If any spring shows signs of fatigue, breakage, or loss of elasticity, replace it immediately. Proper functioning of the springs is vital for the smooth operation of the ratchet and the reliability of the wrench.

Further reading:Why do ratcheting wrenches have two sides? 3 reason you should know

2.Clean and Lubricate

Keeping a ratcheting wrench clean and lubricated is essential for maintaining its performance and extending its lifespan. Regularly disassemble the wrench, remove dirt and grease, inspect parts for wear or damage, and then lubricate with high-quality lubricant to ensure smooth operation and prevent excessive wear.

- Carefully disassemble the ratcheting wrench, paying attention to the position and order of each component.

- Use a clean cloth or brush to remove dirt, grease, and debris from the ratchet and gears.

- For stubborn stains, use an appropriate solvent, ensuring it does not damage the parts.

- Apply high-quality lubricant oil or grease to the gears, ratchet mechanism, and other moving parts.

- Avoid excessive lubrication; a thin layer is sufficient to prevent lubricant buildup and dust attraction.

- Reassemble the wrench in the reverse order of disassembly, ensuring all parts are correctly positioned.

- Gently rotate the ratchet to ensure smooth operation and check the lubrication effectiveness.

Further reading:Why use a ratcheting wrench? 3 reasons to understand

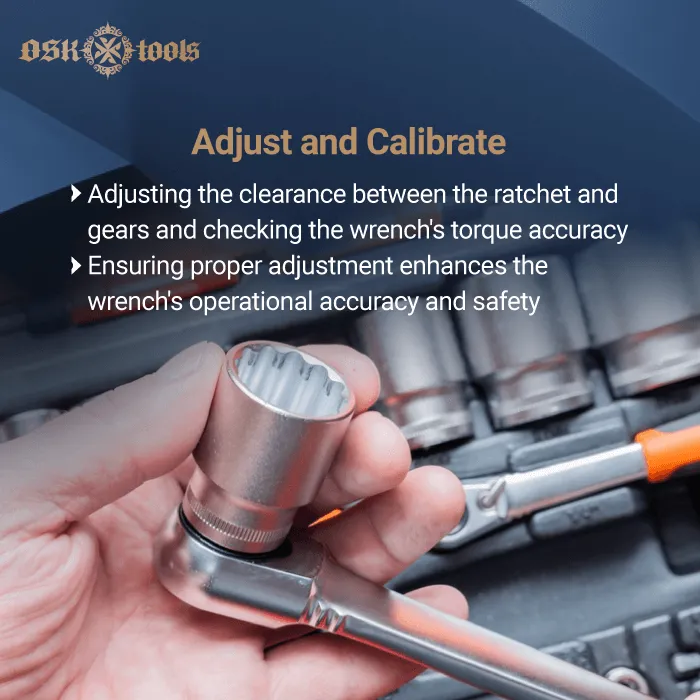

3.Adjust and Calibrate

When maintaining a ratcheting wrench, adjusting and calibrating are crucial steps. First, regularly inspect the ratchet mechanism to ensure smooth operation and the absence of any jamming or irregularities. Check the gap between the ratchet and the gears to see if it is appropriate. If the gap is too large or too small, adjustments may be necessary. If the gap is too large, it can be adjusted by tightening or replacing the adjustment screws; if it is too small, loosening the adjustment screws or replacing with appropriate parts may be required.

Next, use a professional torque tester to calibrate the torque settings of the ratcheting wrench. Gradually increase or decrease the torque according to the manufacturer's specifications until the precise standard value is achieved. After calibration, perform multiple tests to ensure the ratcheting wrench's torque is stable and accurate. Testing should include operations at different torque settings to ensure each setting meets the specifications.

Recommended ratcheting wrench: 【OSK Hand Tools】 96-hour black chrome plating, practical and non-slip

Through this article, you should have gained a certain level of understanding about maintaining a ratcheting wrench. To extend the lifespan of your tools and ensure safety during use, it is important not only to use and maintain the ratcheting wrench correctly but also to carefully select the material and coating of the wrench. Choosing a matte wrench with a black chrome plating can prevent slipping, reduce the risk of drops, and avoid hand injuries, making your repair work safer and more efficient!

We recommend the 【OSK Hand Tools】 brand for ratcheting wrenches. Their tools feature a black chrome coating and have passed a 96-hour salt spray test for durability, ensuring that the coating does not easily peel off, maintaining a comfortable and stable grip. If you need a wrench, head to the wrench section now and make your purchase!

Released on 2024-05-17|Last updated on 2024-05-24 | 961

OSK Tools-Wrench Brand

Phone: +1 949 372 2831(Click to call)

Facebook:OSK Tools(Click to visit)

FB Messenger:OSK Tools(Click to DM)

Service Time: 09:00-18:00 on weekdays