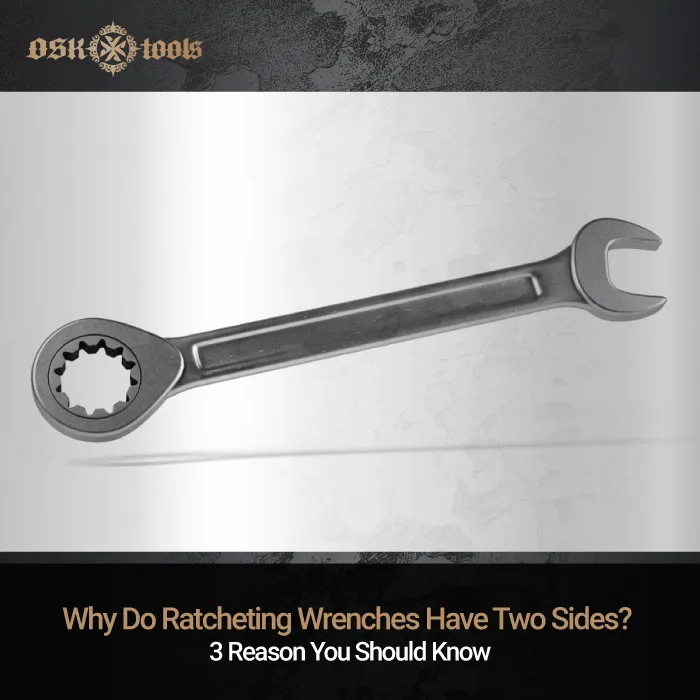

Have you ever held a ratcheting wrench and wondered why it has two sides? In this article, we will explore three key reasons behind this question. Whether you're a seasoned mechanic or just getting acquainted with the tool, this information will help you better understand the principles behind this handy tool.

Table of Contents (Click to read this paragraph)

- Why do ratcheting wrenches have two sides? 3 point tell you the reason▼

- Ratchet Wrench Recommendation: [OSK Hand Tools] Durable Black Chrome Coating, Non-Slip, the Preferred Choice for Maintenance Tools▼

Why do ratcheting wrenches have two sides? 3 point tell you the reason

When you hold a ratcheting wrench, you might be curious why it features a two-sided design. Is it for increased efficiency? Or is it to save costs? In this article, we will uncover three important reasons you should know, shedding light on the design of this tool.

1.Ratcheting wrenches versatility

The two sided design of ratcheting wrenches is primarily aimed at enhancing work efficiency and catering to different requirements in various situations. Here's a detailed explanation of the versatility of ratcheting wrenches.

The two-sided design of ratcheting wrenches enables them to tackle bolts and nuts of different sizes. Typically, each ratcheting wrench features two different-sized sockets, allowing you to effortlessly handle varying sizes of bolts and nuts without the need for tool changes.

Whether it's performing routine maintenance in the garage or undertaking emergency repairs in the field, you can rely on just one ratcheting wrench to handle a variety of situations without the need to carry multiple wrenches of different sizes.

2.Ratcheting wrenches efficiency

The two-sided design of ratcheting wrenches is primarily aimed at enhancing work efficiency. Here's a detailed, professional breakdown of efficiency

a.Reduction of Work Time

The two-sided design of ratcheting wrenches allows users to accomplish multiple actions in a single operation. This eliminates the need to switch tools between each action, thus saving valuable work time.

b.Decreased Muscle Fatigue

Compared to traditional wrenches, operating a ratcheting wrench is less strenuous. Due to its ratcheting mechanism, users only need to rotate in one direction without the need for back-and-forth motions with each action, reducing muscle fatigue and improving work efficiency.

c.Adaptability to Different Work Environments

The two-sided design of ratcheting wrenches makes them suitable for various work environments, including tight spaces and hard-to-reach locations. This makes them an ideal choice for working in diverse settings, thereby improving overall work efficiency.

Further reading:Is a ratchet better than a wrench? 3 topic analysis

3.Ratcheting wrenches space-saving

One of the primary reasons why ratcheting wrenches are designed with two sides is to save space.

The two-sided design of ratcheting wrenches allows for an extremely compact structure, combining two different-sized wrenches into a single unit. Such a design saves storage and transportation space, which is particularly important in workplaces with limited space.

Further reading:What is the best size ratcheting wrench? 4 common sizes introduction

With the two-sided design of ratcheting wrenches, users can handle different sizes of bolts and nuts with a single wrench, eliminating the need to carry multiple wrenches of different sizes. This not only reduces the quantity of tools but also decreases the required storage space.

The two-sided design of ratcheting wrenches makes them easier to store and carry. Users can conveniently place a ratcheting wrench in a toolbox or the trunk of a vehicle without taking up too much space, which is particularly useful in situations requiring frequent tool movement.

Ratchet Wrench Recommendation: [OSK Hand Tools] Durable Black Chrome Coating, Non-Slip, the Preferred Choice for Maintenance Tools

Through this article, everyone can gain a deeper understanding of why ratcheting wrenches have two sides. Two-sided ratcheting wrenches make maintenance work smoother, eliminating the need to frequently switch tools and reducing the number of tools to carry. They also make various maintenance tasks more convenient to perform. When choosing double-sided ratcheting wrenches, it is recommended to consider the material and coating of the wrench to ensure convenience and safety during prolonged use.

It is advisable to choose sturdy and durable matte finish ratcheting wrenches with black chrome plating, which prevent slipping and ensure that the wrenches do not fall off. They also resist fatigue even with prolonged multi-directional rotations. Recommended ratcheting wrenches from [OSK Hand Tools] employ black chrome plating, passing the 96-hour salt spray test, ensuring long-lasting usability. If you have wrench needs, head over to the wrench section now to make your purchase!

Released on 2024-05-10|Last updated on 2024-05-17 | 2029

OSK Tools-Wrench Brand

Phone: +1 949 372 2831(Click to call)

Facebook:OSK Tools(Click to visit)

FB Messenger:OSK Tools(Click to DM)

Service Time: 09:00-18:00 on weekdays